Optimizing Cold Chain Operations: On-Demand Chiller Control through Integrated Temperature Monitoring

Zomato Blinkit

UN SDG 9 - Industry, Innovation and Infrastructure

Bengaluru, India

Pain Points

Uncontrolled cooling caused energy loss and temperature imbalance in cold storage areas.

Invisible Energy Wastage

Chillers operated continuously without demand awareness, leading to unnecessary energy usage.

Risk of Product Spoilage

High temperatures affected product quality, while overcooling increased power consumption.

Manual Cooling Operations

Lack of automation resulted in inefficient temperature control across dark store cold storage.

Our Offerings

IoT-based temperature monitoring with automated, demand-driven chiller control.

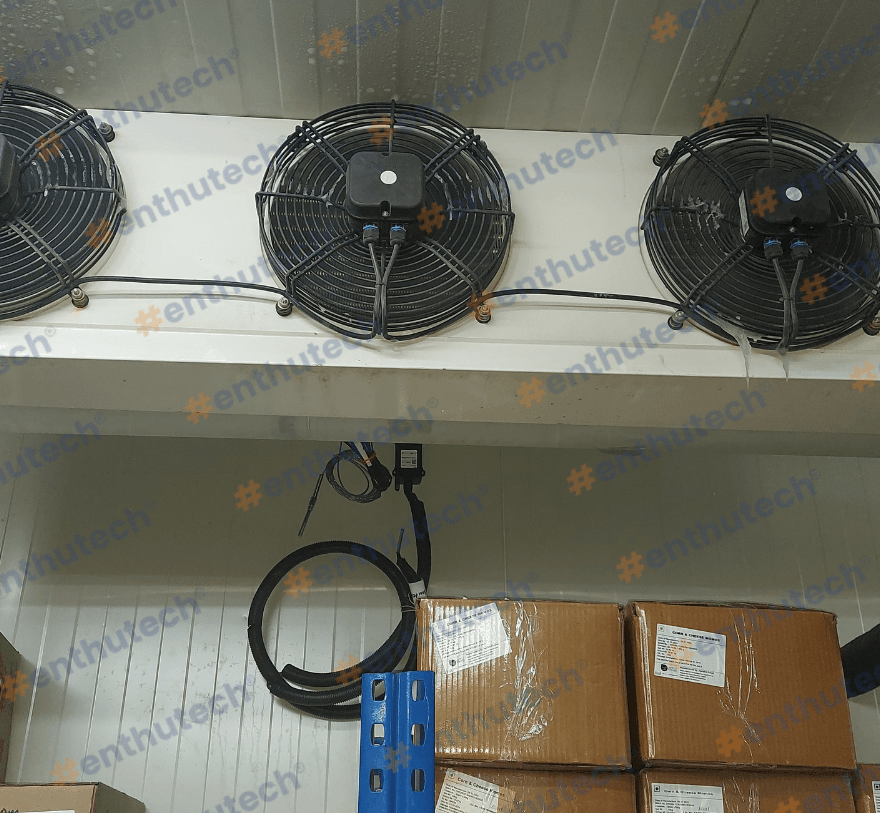

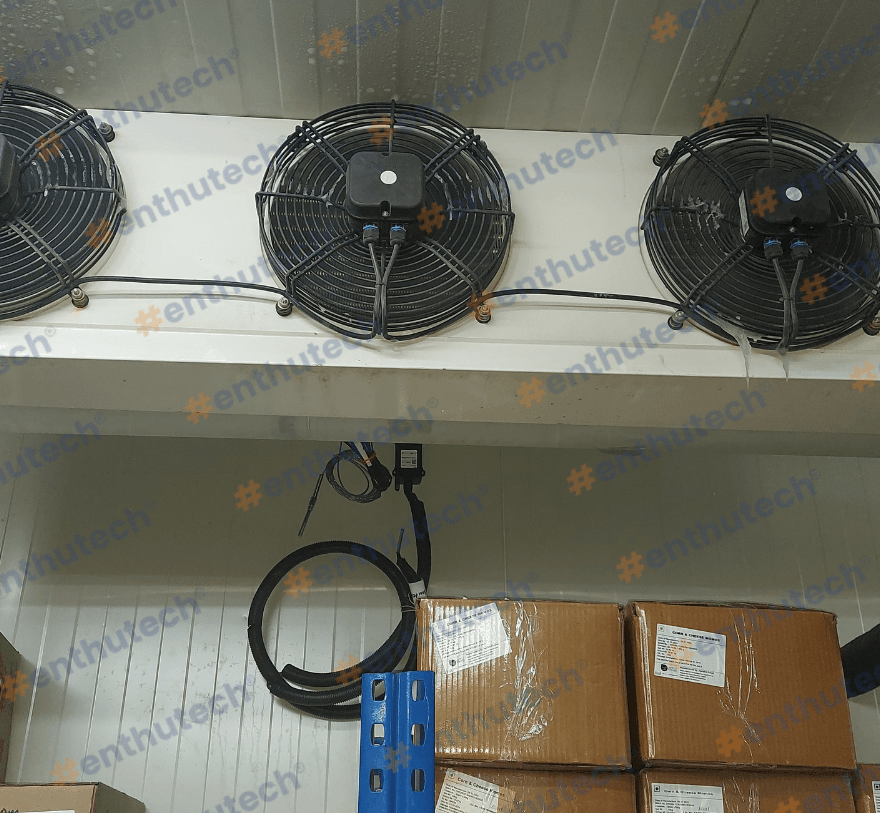

Cold Storage Temperature Monitoring

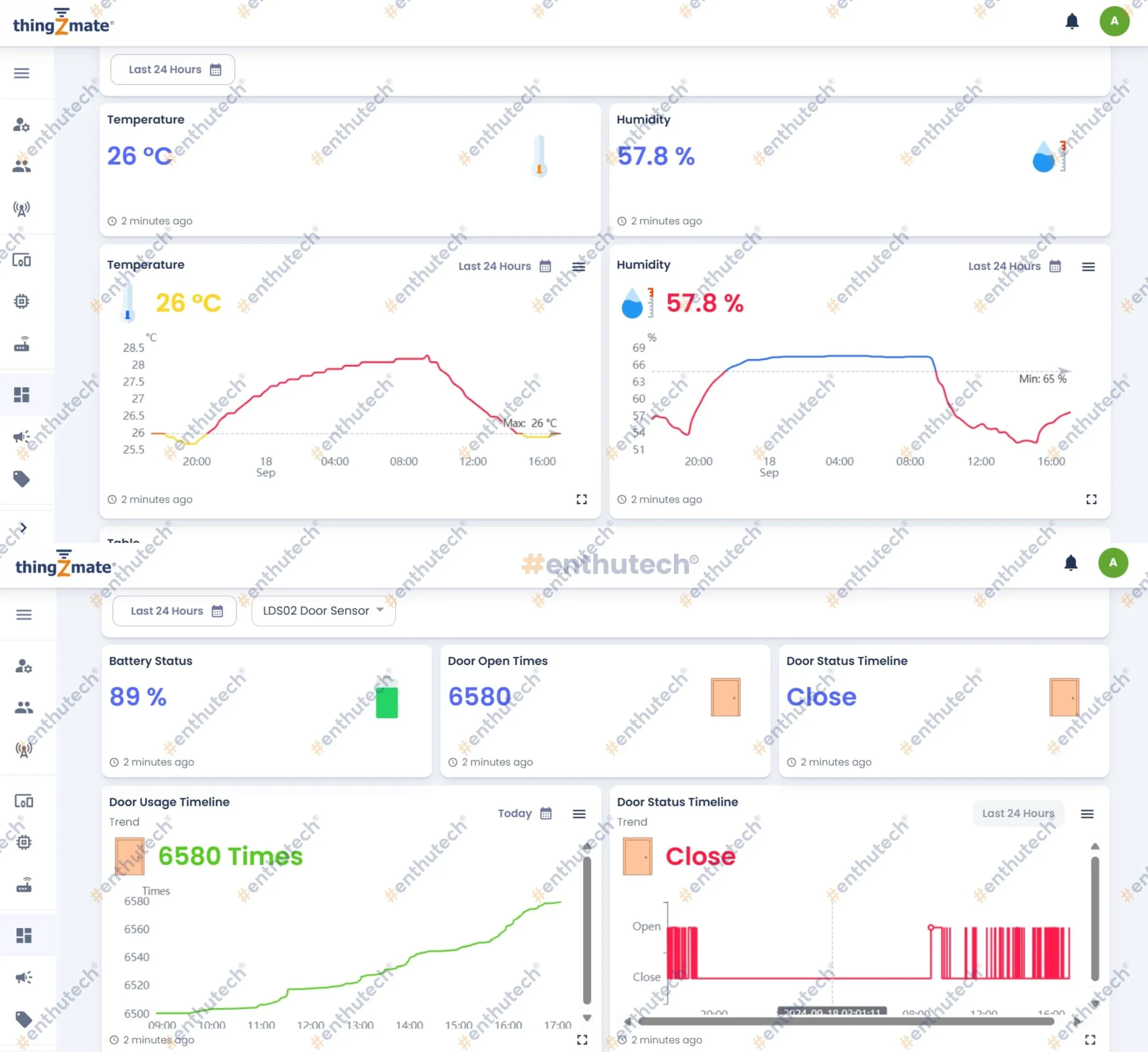

Continuous temperature data collection across cold storage zones for real-time visibility.

On Demand Chiller Control

Chillers activated only when temperature crossed defined thresholds.

Temperature Analytics

Historical and live analytics helped identify overcooling and inefficiencies.

Optimized Cooling Logic

Automated control logic balanced food safety with energy efficiency.

Outcomes

10–15% Energy Savings

Eliminated unnecessary chiller runtime through demand-based operation.

Consistent Cold Storage Temperatures

Maintained optimal temperature ranges for perishable product safety.

Reduced Product Spoilage

Improved temperature control minimized spoilage risks in dark stores.

Operational Efficiency

Automated cooling reduced manual intervention and operational dependency.

On-demand cooling helped achieve 10–15% energy savings while protecting inventory.

On-demand cooling helped achieve 10–15% energy savings while protecting inventory.

Get in Touch

© 2025, Enthu Technology Solutions India Pvt. Ltd. All Rights Reserved.